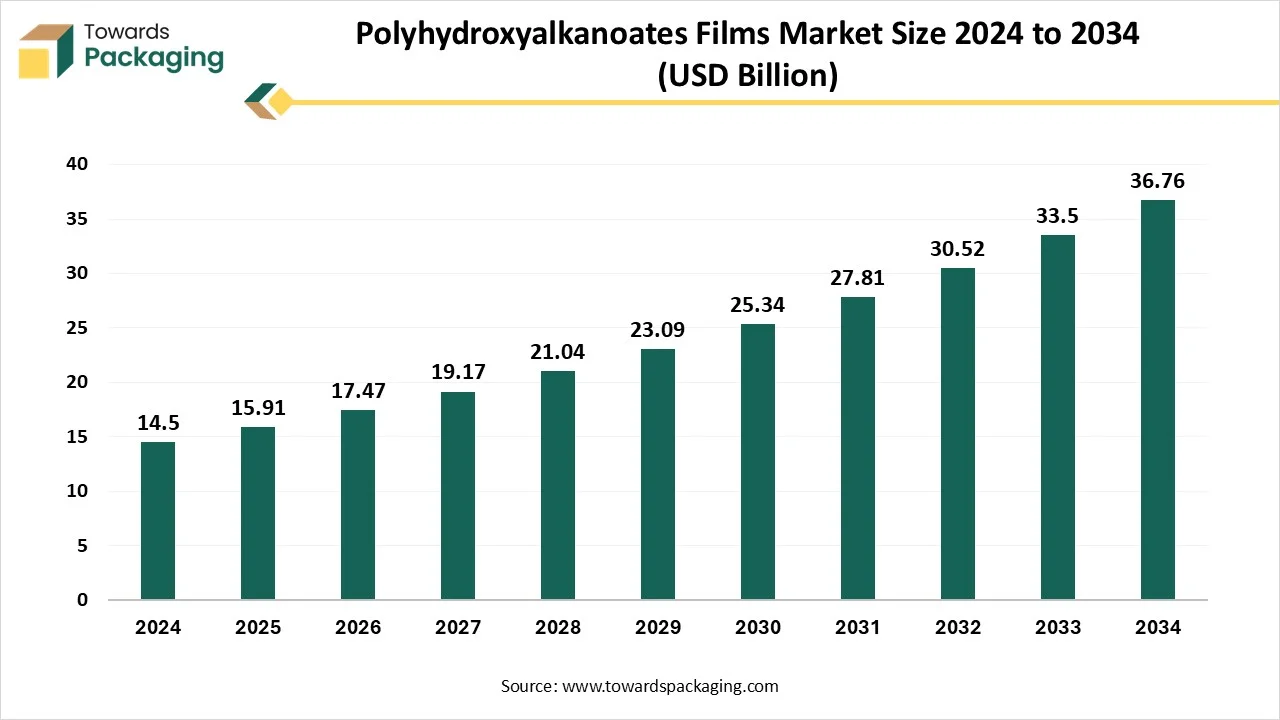

Polyhydroxyalkanoates Films Market to Worth USD 36.76 Bn by 2034

According to Towards Packaging consultants, the global polyhydroxyalkanoates films market is projected to reach approximately USD 36.76 billion by 2034, increasing from USD 17.47 billion in 2026, at a CAGR of 9.75% during the forecast period 2025 to 2034.

Ottawa, Oct. 23, 2025 (GLOBE NEWSWIRE) -- The global polyhydroxyalkanoates films market, valued at USD 15.91 billion in 2025, is expected to rise to approximately USD 36.76 billion in 2034, based on a report published by Towards Packaging, a sister firm of Precedence Research.

Get All the Details in Our Solutions - Access Report Sample: https://www.towardspackaging.com/download-sample/5665

The market growth is driven by growing environmental concerns and regulations against plastic pollution, the rising adoption of advanced biotechnological methods to enhance PHA yields and lower expenses, the growth of diverse applications in packaging, agriculture, and the biomedical sector, and a heightened regional focus on production and integration, mainly in the Asia-Pacific.

What are Polyhydroxyalkanoates Films?

Polyhydroxyalkanoate (PHA) films are thin sheets made from polyhydroxyalkanoates, which are generally naturally occurring biodegradable polyesters manufactured by microorganisms as energy and carbon storage. The primary driver is the increasing market demand for alternatives to conventional petroleum-based plastics that are biodegradable and compostable. Governments and environmental agencies are implementing stricter regulations against plastic use and waste, which impacts the adoption of sustainable materials, such as PHA films.

What are the Latest Trends in the Polyhydroxyalkanoates Films Market?

-

Growing adoption due to increasing regulations against plastic pollution

Governments globally are enacting bans and restrictions on single-use plastics, creating a regulatory environment that favors sustainable alternatives such as PHA films. Consumers are increasingly choosing goods from eco-conscious brands, pushing firms to integrate biodegradable materials into their supply chains.

-

Technological Advancements Enhancing Film Properties

Innovations in fermentation processes, polymer extraction, and film processing are enhancing the mechanical properties and shelf life of PHA films. Blending PHA with complementary materials enables customization to meet specific industry needs, thereby broadening the scope of applications.

If there is anything you'd like to ask, feel free to get in touch with us @ sales@towardspackaging.com

What Potentiates the Growth of the Polyhydroxyalkanoates Films Market?

The growing need for biodegradable and sustainable materials significantly drives the market by creating a greater demand for eco-friendly options to traditional plastics, encouraging investment in polyhydroxyalkanoates production and innovation. Stricter government regulations targeted at reducing plastic waste and encouraging eco-friendly alternatives, thus accelerate the shift toward biodegradable films. The ability to manufacture polyhydroxyalkanoates from waste materials, such as agricultural residues, food waste, and used oils, has led to a circular economy and decreased reliance on virgin resources.

Limitations & Challenges in Polyhydroxyalkanoates Films Market

Substrate expenses, low yields, and complex extraction and purification processes significantly contribute to high overall production expenses, making polyhydroxyalkanoates less competitive than traditional plastics. Achieving high yields and even productivity of polyhydroxyalkanoate via microbial fermentation remains a significant barrier to economic feasibility. The restricted range of functionalities in some polyhydroxyalkanoates limits their application in specific industrial and commercial sectors.

Regional Analysis

Who is the Leader in the Polyhydroxyalkanoates Films Market?

Europe dominated the market in 2024. A high level of environmental consciousness among European consumers drives the need for eco-friendly packaging solutions, which in turn impacts businesses to invest in sustainable options. Europe is home to major global bioplastics players who invest in research and development (R&D) and even bioplastic technology, contributing to innovative and cost-effective solutions for biodegradable films. As Europe's largest economy, Germany's commitment to environmental sustainability and even its robust industrial base are key factors in its leadership within the market.

UK Market Trends

The UK's market is experiencing strong growth, driven by the rising need for sustainable packaging, agricultural, and medical films, along with government support for biopolymers.

How is the Opportunistic Rise of Asia-Pacific in Polyhydroxyalkanoates Films Market?

Asia-Pacific is expected to experience the fastest growth in the market because of strong environmental concerns, supportive government regulations against plastic waste, and the rising need for sustainable packaging. Industries, primarily in the food and beverage sector, are increasingly seeking eco-friendly solutions for packaging, which polyhydroxyalkanoate films provide.

More Insights of Towards Packaging:

- Box and Carton Overwrap Films Market Drives at 4.5% CAGR - The box and carton overwrap films market is projected to reach USD 23.06 billion by 2034, expanding from USD 15.52 billion in 2025.

- Shrink Label Films Market Driven by 5.12% CAGR - The shrink label films market is forecast to grow at a CAGR of 5.12%, from USD 11,417.03 million in 2025 to USD 17,893.18 million by 2034.

- High-Barrier Packaging Films Market Review, Key Business Drivers and Industry Forecast - The high-barrier packaging films market is projected to reach USD 62.66 billion by 2034, expanding from USD 36.62 billion in 2025.

- Print-receptive PE films Market Key Trends, Disruptions and Strategic Imperatives - The print-receptive PE films market is booming, poised for a revenue surge into the hundreds of millions from 2025 to 2034.

- North America High-Barrier Packaging Films Market Size and Growth Forecast - The North America high-barrier packaging films market is expected to increase from USD 11.01 billion in 2025 to USD 19.12 billion by 2034.

- PCTFE Pharmaceutical Packaging Films Market 2025 Share, Trends, and Forecast at 5.3% CAGR to 2034 - The PCTFE pharmaceutical packaging films market is set to grow from USD 1000.35 million in 2025 to USD 1592.24 million by 2034.

- Packaging Films Market Drives at 5% CAGR (2025-34) - The global packaging films market is projected to reach USD 179.18 billion by 2034, expanding from USD 115.5 billion in 2025.

- Cling Films Market Trends Accelerating in 2025 with Long-Term Forecast of USD 2.45 Billion - The global cling films market is forecast to grow from USD 13.06 billion in 2025 to USD 19.41 billion by 2034, driven by a CAGR of 12.5% from 2025 to 2034.

- Sustainable Films for Packaging Market Analysis 2025: Europe Leads With Strong Eco-Regulations - The global sustainable films for packaging market is projected to reach USD 392.7 billion by 2034, expanding from USD 191.04 billion in 2025.

- PVC Packaging Film Market Surges in 2025 with 25% Spike in Flexible Demand and 15% Uptick in Recycled Use - The polyvinyl chloride packaging film market is projected to reach USD 17.48 billion by 2034, growing from USD 14.06 billion in 2025.

- UV Resistant Films Market Growth Drivers, Challenges, Opportunities and Leading Players - The UV-resistant films market is set to grow from USD 3.66 billion in 2025 to USD 6.37 billion by 2034, with an expected CAGR of 6.43% over the forecast period from 2025 to 2034.

- Metalized Biaxially Oriented Polypropylene Films Market Key Players and Investment Trends - The cellulose film packaging market is forecast to grow from USD 940.11 million in 2025 to USD 1532.98 million by 2034, driven by a CAGR of 5.63% from 2025 to 2034.

- Specialty Films Market Drives at 2.33% CAGR (2025-34) - The global specialty films market is expected to increase from USD 22.13 billion in 2025 to USD 27.16 billion by 2034, growing at a CAGR of 2.33% throughout the forecast period.

- BOPP Films Market Drives at 5.34% CAGR (2025-34) - The global BOPP films market is set to grow from USD 31.51 billion in 2025 to USD 50.16 billion by 2034.

-

Agricultural Films Market Driven by 5.94% CAGR (2025-34) - The agricultural films market is expected to increase from USD 12.52 billion in 2025 to USD 21.02 billion by 2034, growing at a CAGR of 5.94% throughout the forecast period.

Segment Outlook

Type of PHA Polymer Insights

The short-chain length (scl-PHA) segment dominated the polyhydroxyalkanoates films market in 2024. This is due to its balance of superior mechanical properties, excellent barrier performance, and cost-effectiveness compared to some PHA types. Microbes synthesize these compounds to mimic the features of conventional plastics, which facilitates their market acceptance. Stringent environmental regulations and a worldwide focus on reducing plastic waste drive the need for biodegradable alternatives such as s-PHA films.

The medium-chain length (mcl-PHA) is the fastest-growing segment in the market due to its inherent tailorability, which permits a broad range of mechanical properties and is desirable for applications requiring improved flexibility and durability. The chemical composition of mcl-polyhydroxyalkanoates is highly diverse, enabling the creation of copolymers with specific mechanical and thermal properties that meet various application needs, ranging from flexible packaging to advanced medical devices.

Production Method Insights

The bacterial fermentation of sugars/starches segment dominated the polyhydroxyalkanoates films market in 2024, as sugars and starches are readily available, usually derived from renewable agricultural and even food waste, creating inexpensive carbon sources for microbial fermentation. The purity and consistent quality of sugar and starch feedstocks enable the careful design of the polymer's molecular framework, resulting in performance-oriented materials.

The fermentation of waste oils/fats segment is expected to grow at the fastest rate during the forecast period. It offers a low-cost, sustainable carbon source for microbial production, decreasing overall polyhydroxyalkanoates expenses and leading to environmental pollution reduction. Waste oils and fats, primarily waste cooking oils, are abundant and readily available globally, providing a consistent and inexpensive source of the necessary carbon for polyhydroxyalkanoates synthesis.

Join now to access the latest packaging in industry segmentation insights with our Annual Membership: https://www.towardspackaging.com/get-an-annual-membership

Film Type Insights

The monolayer films segment dominated the polyhydroxyalkanoates films market in 2024. This is mainly due to their simplicity in production and even suitability for single-use applications such as packaging and agriculture. They are inherently biodegradable and even compostable, making them excellent for single-use applications where sustainability is a high concern. Monolayer films effectively use this property for products such as packaging and agricultural mulches.

The multilayer films segment is likely to expand at the fastest CAGR in the upcoming period. Advancements in biopolymer engineering have enhanced polyhydroxyalkanoate films with improved oxygen and moisture barriers, enhanced heat resistance, and improved sealing properties, allowing them to rival traditional plastic films. Rising investments in biopolymer production capacity, combined with ongoing technological development in materials processing, decrease production expenses and enhance efficiency, making polyhydroxyalkanoate films more scalable and affordable.

Thickness Insights

The 20-50 microns segment dominated the polyhydroxyalkanoates films market in 2024, as it provides an optimal balance between durability and the desired degradation rate for many applications, mainly agricultural mulch films and packaging. By utilizing a moderate amount of material compared to thicker films, producers can achieve cost savings while still meeting performance needs, a key factor for commercial growers and businesses.

The <20 microns segment is the fastest-growing segment in the polyhydroxyalkanoates films market during the forecast period. As thinner films utilize less material, saving expenses, they can be improved with nanotechnology to handle performance while reducing thickness. The advancement of nanotechnology permits the creation of thinner polyhydroxyalkanoate films without sacrificing their significant performance characteristics, like barrier properties and strength. Thin polyhydroxyalkanoate films are increasingly utilized in retail-ready packaging and even as secondary wrapping in the distribution of FMCG products.

Elevate your packaging strategy with Towards Packaging. Enhance efficiency and achieve superior results - schedule a call today: https://www.towardspackaging.com/schedule-meeting

Application Insights

The food packaging segment dominated the polyhydroxyalkanoates films market in 2024. As a bio-driven polymer produced by microorganisms, polyhydroxyalkanoates offer a sustainable alternative to fossil fuel-based plastics, thereby reducing the environmental footprint of packaging. Nanotechnology, along with advancements in biopolymer processing techniques, is improving the functional properties of polyhydroxyalkanoates, making them more appealing and effective for food packaging.

The biomedical segment is expected to grow at the fastest rate during the forecast period. Polyhydroxyalkanoate films are non-toxic, and also their ability to degrade naturally within the body is important for medical devices and implants. The medical and hygiene industries are rapidly shifting towards sustainable and environmentally friendly materials to support global sustainability goals. Stricter government regulations on traditional plastic waste are indirectly encouraging the use of biodegradable materials, such as polyhydroxyalkanoates, in all sectors, including medicine.

End-Use Industry Insights

The food and beverage segment dominated the polyhydroxyalkanoates films market in 2024. Polyhydroxyalkanoate films are biodegradable and compostable, working with the industry's demand for sustainable options to conventional plastics. Governments are implementing bans and restrictions on single-use plastics, prompting the food and beverage industry to adopt biodegradable materials, such as polyhydroxyalkanoate films, for packaging. Polyhydroxyalkanoates are utilized in numerous food packaging applications, including wrapping films for manufacturing, containers for ready-to-eat meals, and coatings for products such as paper cups for hot beverages.

The healthcare industry segment is expected to expand at the fastest CAGR in the upcoming period. Polyhydroxyalkanoates are recognized for being safe for use in the human body and can also break down naturally, which is important for medical implants and drug delivery systems. Beyond packaging, polyhydroxyalkanoates are utilized in the creation of sutures, tissue engineering scaffolds, surgical meshes, and cardiovascular stents, which are high-value products for the medical field. Manufacturers are developing new polyhydroxyalkanoates-driven products for niche medical applications, creating a competitive edge, and unlocking high-margin medical markets.

Distribution Channel Insights

The direct sales (B2B) segment dominated the polyhydroxyalkanoates (PHA) films market because it enables timely, bulk, and even customized material supplies, which are vital for large-scale industrial applications such as food packaging and biomedical products. Direct relationships enable producers and their clients to collaborate on specific film requirements, such as tailored mechanical properties, targeted barrier characteristics, and desired dimensions.

The online platforms segment is the fastest-growing segment in the market due to the increase in e-commerce and the need for sustainable packaging solutions that work with the growing consumer and retailer preference for eco-friendly materials, such as PHA, to combat plastic pollution. Major firms, including retailers and e-commerce giants, are committed to reducing plastic use and adopting biopolymer options, such as PHA, for their packaging to align with sustainability goals.

Access our exclusive, data-rich dashboard dedicated to the Polyhydroxyalkanoates Films Market - built specifically for decision-makers, strategists, and industry leaders. The dashboard features comprehensive statistical data, segment-wise market breakdowns, regional performance shares, detailed company profiles, annual updates, and much more. From market sizing to competitive intelligence, this powerful tool is one-stop solution to your gateway.

Access Now: https://www.towardspackaging.com/contact-us

Recent Development

- In June 2025, Teknor Apex, a worldwide leader in plastic material science solutions, is pleased to announce the acquisition of Danimer Scientific, a leading bioplastics firm focused on the development and production of biodegradable materials

Top Polyhydroxyalkanoates Films Market Players

- Danimer Scientific

- RWDC Industries

- Newlight Technologies

- Bio-on

- TianAn Biologic Materials

- Yield10 Bioscience

- NaturePlast

- Bluepha Co., Ltd.

- Kaneka Corporation

- Mango Materials

- Full Cycle Bioplastics

- Tepha Inc.

Segments Covered in the Report

By Type of PHA Polymer

- Short-Chain Length (scl-PHA) (C3-C5 carbon atoms)

- Poly(3-hydroxybutyrate) (PHB)

- Poly(3-hydroxyvalerate) (PHV)

- Medium-Chain Length (mcl-PHA) (C6-C14 carbon atoms)

- Poly(3-hydroxyhexanoate) (PHHx)

- Poly(3-hydroxyoctanoate) (PHO)

- Poly(3-hydroxydecanoate) (PHD)

By Production Method

- Bacterial Fermentation of Sugars/Starches

- Fermentation of Waste Oils/Fats

- Genetically Modified Microorganisms

By Film Type

- Monolayer Films

- Multilayer Films

- Coated Films

By Thickness

- <20 microns

- 20–50 microns

- >50 microns

By Application

- Packaging

- Food Packaging

- Cosmetic Packaging

- Industrial Packaging

- Agriculture

- Mulch Films

- Greenhouse Films

- Biomedical

- Wound Dressing Films

- Drug Delivery Films

- Compost Bags and Liners

- Textiles

- Others (e.g., stationery, coatings)

By End-Use Industry

- Food and Beverage

- Agriculture

- Healthcare

- Cosmetics and Personal Care

- Retail

- Industrial/Manufacturing

By Distribution Channel

- Direct Sales (B2B)

- Distributors and Wholesalers

- Online Platforms

By Geography

- North America

- U.S.

- Canada

- Europe

- U.K.

- Germany

- France

- Asia-Pacific

- China

- India

- Japan

- South Korea

- Malaysia

- Philippines

- Latin America

- Brazil

- Rest of Latin America

- Middle East & Africa (MEA)

- GCC

- North Africa

- South Africa

- Rest of the Middle East & Africa

Invest in Our Premium Strategic Solution: https://www.towardspackaging.com/price/5665

Become a Valued Research Partner with Us - Schedule a meeting: https://www.towardspackaging.com/schedule-meeting

Request a Custom Case Study Built Around Your Goals: sales@towardspackaging.com

About Us

Towards Packaging is a global consulting and market intelligence firm specializing in strategic research across key packaging segments including sustainable, flexible, smart, biodegradable, and recycled packaging. We empower businesses with actionable insights, trend analysis, and data-driven strategies. Our experienced consultants use advanced research methodologies to help companies of all sizes navigate market shifts, identify growth opportunities, and stay competitive in the global packaging industry.

Stay Connected with Towards Packaging:

- Find us on Social Platforms: LinkedIn | Twitter | Instagram

- Subscribe to Our Newsletter: Towards Sustainable Packaging

- Visit Towards Packaging for In-depth Market Insights: Towards Packaging

- Read Our Printed Chronicle: Packaging Web Wire

-

Get ahead of the trends – follow us for exclusive insights and industry updates:

Pinterest | Medium | Tumblr | Hashnode | Bloglovin | LinkedIn – Packaging Web Wire - Contact: APAC: +91 9356 9282 04 | Europe: +44 778 256 0738 | North America: +1 8044 4193 44

Towards Packaging, Your Trusted Research and Consulting Partner, Has Been Featured Across Influential Industry Portals - Explore the Coverage:

- Flexible Packaging Market - PACKNODE

- Is it finally safe to ditch your phone case? I put it to the test

- Battery Brands Charge Forward with Plastic-Free Packaging

- Why Non-corrugated Boxes Are the Future of Packaging

- Ampoules Packaging Market Size Expected to Reach $11.27 Bn by 2034

- Flexible plastic pouches projected to boom over the next decade

- GLOBAL PET FOOD PACKAGING MARKET SET TO DOUBLE BY 2032

- The Skinny on the Skin Packaging Market

- Healthcare Goes Green & Sterile

- The Different Types of Adhesives for Paper Packaging

-

Child-Resistant Packaging: Cannabis and So Much More

Towards Packaging Releases Its Latest Insight - Check It Out:

- Protective Films Market Set for 6.27% CAGR Growth Driven by EVs and Smart Packaging

- Food Packaging Films Market Evolve to Meet Hygiene, Shelf Life, and Regulatory Needs

- Vehicle Wrapping PVC Film Market Boom: How Color, Branding, and Tech Are Transforming the Roadscape

- Medical Packaging Films Market 2025 Driven by Demand Reaching USD 17.65 Billion by 2034

- Mono-material Plastic Packaging Film Market Playbook, Growth Opportunities and Trends

- Metallized Rollstock Film Market Key Trends, Disruptions and Strategic Imperatives

- Clear Plastic Film Market Investment Opportunities & Competitive Benchmarking

- Biobased Films Market Consumer Insights & Growth Strategies

- Transparent Barrier Packaging Films Market Growth, Innovations, and Market Size Forecast 2034

- Recyclable Shrink Film Market Research, Consumer Behavior, Demand and Forecast

- Stretch Hooder Packaging Film Market Dynamics, Competitive Forces & Strategic Pathways

- Tire Packaging Film Market Outlook Scenario Planning & Strategic Insights for 2034

- Pharmaceutical APET Film Market Research, Consumer Behavior, Demand and Forecast

- PET VCI Shrink Film Market Research Insight: Industry Insights, Trends and Forecast

-

Electronics APET Film Market Strategic Growth, Innovation & Investment Trends

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.